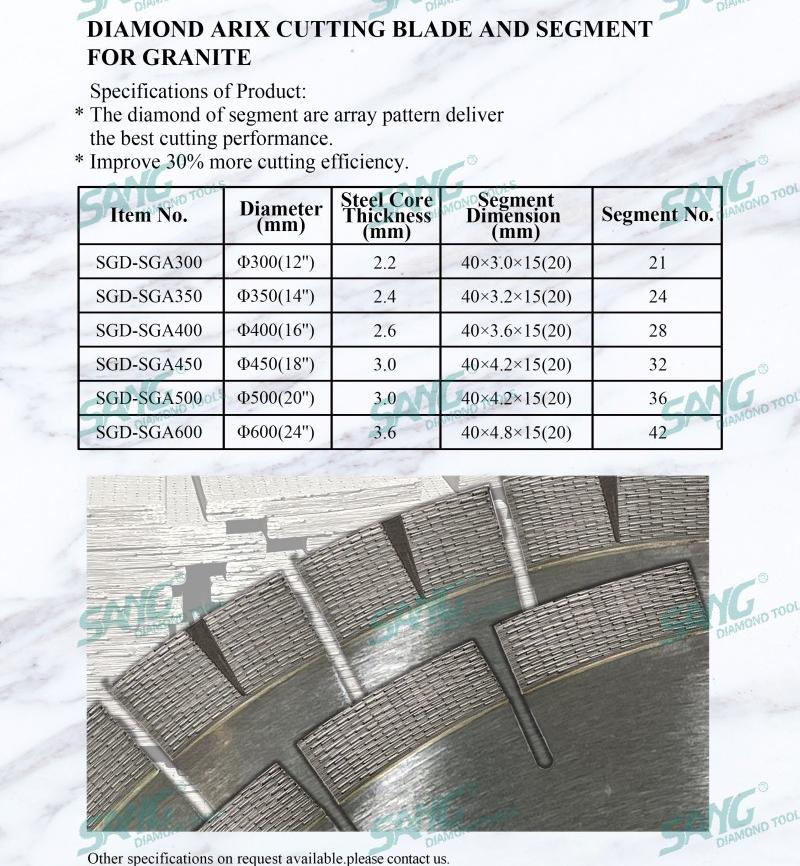

În lumea prelucrării pietrei, aflată în continuă evoluție, precizia și eficiența nu mai sunt opționale - sunt esențiale. La SANG Diamond Tools, suntem mândri să vă prezentăm

400mm diameter Arix Diamond Saw Blade

, a cutting-edge innovation that is transforming how professionals cut granite, quartz, and other engineered stones.

The Evolution of Diamond Saw Technology

Traditional diamond saw blades rely on randomly scattered abrasive grains, often resulting in inefficiencies, uneven wear, and inconsistent cutting performance. Our

Arix Diamond Saw Blade

changes the game entirely, with a geometrically ordered diamond matrix that ensures each diamond grain is placed with mathematical precision—like a well-organized army moving in perfect formation.

What Sets the 400mm Diamond Saw Blade Apart?

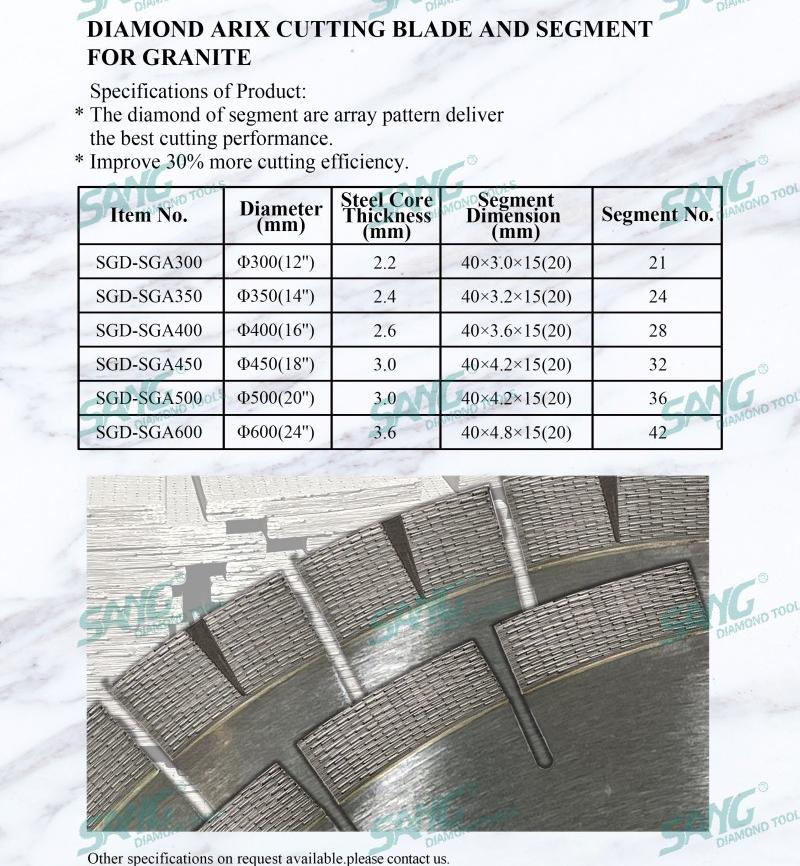

1. Ordered Diamond Distribution

Using advanced computer simulation and fluid dynamics, each diamond grain is strategically placed to maximize cutting efficiency and reduce waste material. This optimized pattern enhances both the blade's aggressiveness and stability during operation.

2. Differentiated Zoning Layout

The cutting zone is densely packed to ensure faster and deeper cuts, while the side zones are engineered to minimize friction—striking a perfect balance between speed and precision.

3. Custom Metal Bond Formulation

Our proprietary metal bond provides superior holding strength for the diamonds while maintaining self-sharpening properties. This innovation extends the blade’s lifetime and reduces the frequency of blade replacement.

Cutting-Edge Performance Backed by Data

Statistical testing and real-world client feedback validate the superior performance of the

400mm Diamond Saw Blade

:

35–40% increase in cutting efficiency for granite

25–30% increase in cutting speed for quartz

Over 200 hours of stable operation on granite with Mohs hardness 7–8

50% longer lifespan compared to traditional blades

70% reduction in edge chipping

Thickness tolerance within ±0.15mm, reducing the need for secondary polishing

These benefits do more than improve productivity—they directly reduce energy consumption, optimize raw material usage, and minimize waste, aligning with both environmental and operational goals.

Why Choose

SANG’s Arix Diamond Saw Blade

?

Predictable Performance Through Quality Control

Every blade undergoes strict internal testing to ensure it meets our high standards. We don’t just deliver blades—we deliver reliability.

Custom Solutions for Every Application

Whether you're cutting dense black granite or delicate engineered quartz, we offer tailored configurations:

Adjustable diamond grit size and concentration

Customized segment heights and widths

Compatibility optimization for bridge saws and manual cutters

Eco-Friendly and Cost-Efficient

Longer lifespan means fewer replacements. Higher precision means less waste. Greater efficiency means lower power bills. With the 400mm diameter Arix Diamond Saw Blade, you get a triple win in performance, cost, and sustainability.

Final Thoughts: Leading the Future of Stone Cutting

The Arix Diamond Saw Blade isn't just another tool—it's a technological advancement designed to meet the rigorous demands of modern stone processing. By integrating precision engineering, intelligent design, and sustainable thinking, SANG Diamond Tools is helping fabricators and manufacturers reshape their production lines—literally and figuratively.

If you're ready to elevate your cutting performance, reduce costs, and future-proof your operations, it's time to switch to the 400mm Diamond Saw Blade by SANG.